- Home

- About Us

-

Products

Automation Components

- MCB, MCCB, Contactors

- Thermal Overload Relays, MPCB, Motor Starters, Changeover Switches

- HRC Fuses, Capacitors, Meters, Distribution Boards

- AC/DC Drives, Power Supplies, SMPS, Hour Meters & Counters

- PLC Controllers, HMI, Alarm Annunciators, PID & Temperature Controllers

- Proximity Sensors & many more.

Electrical Supplies

Pneumatics & Instruments

Industrial Engineering Components

- Brands

- Services

- Gallery

- Contact

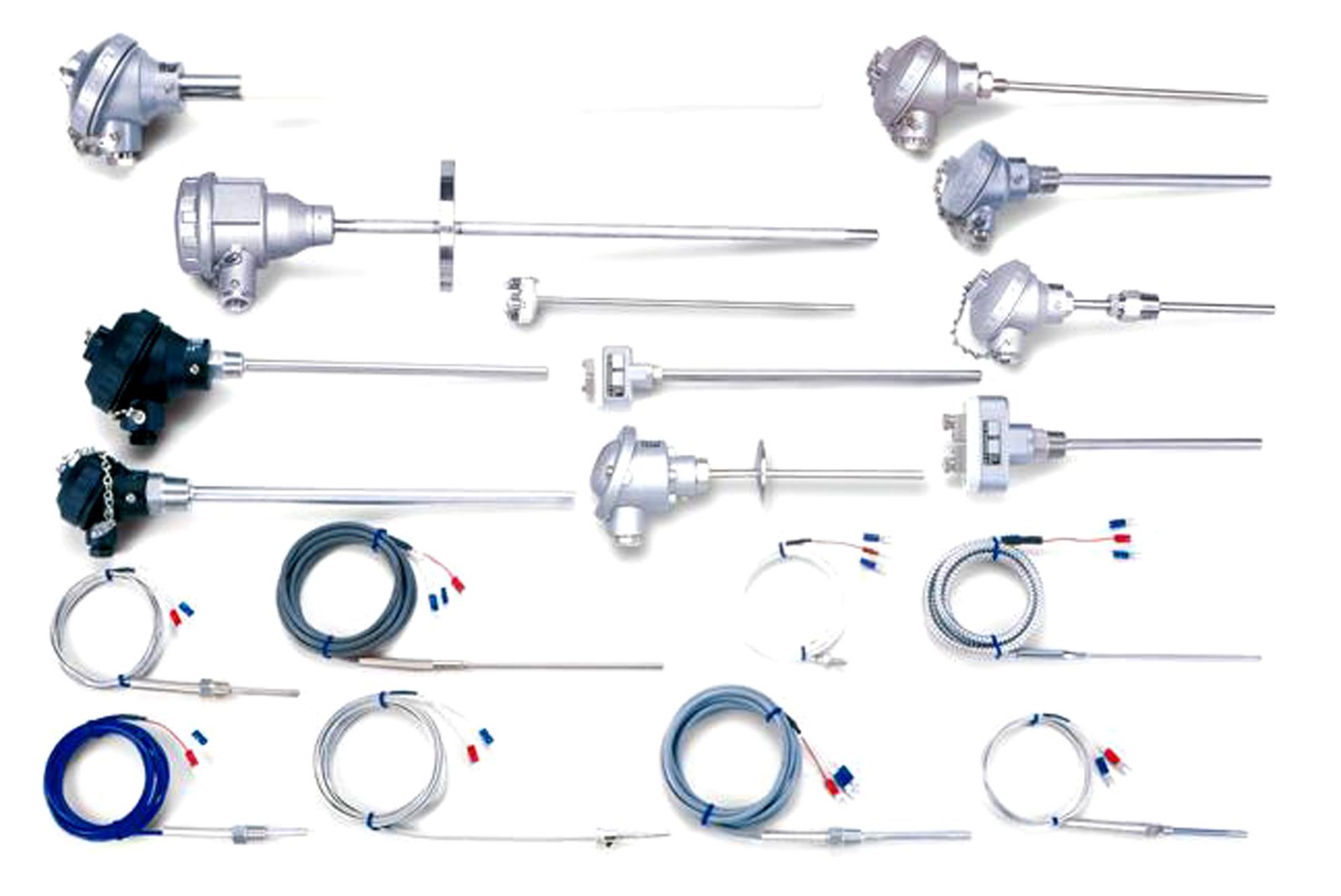

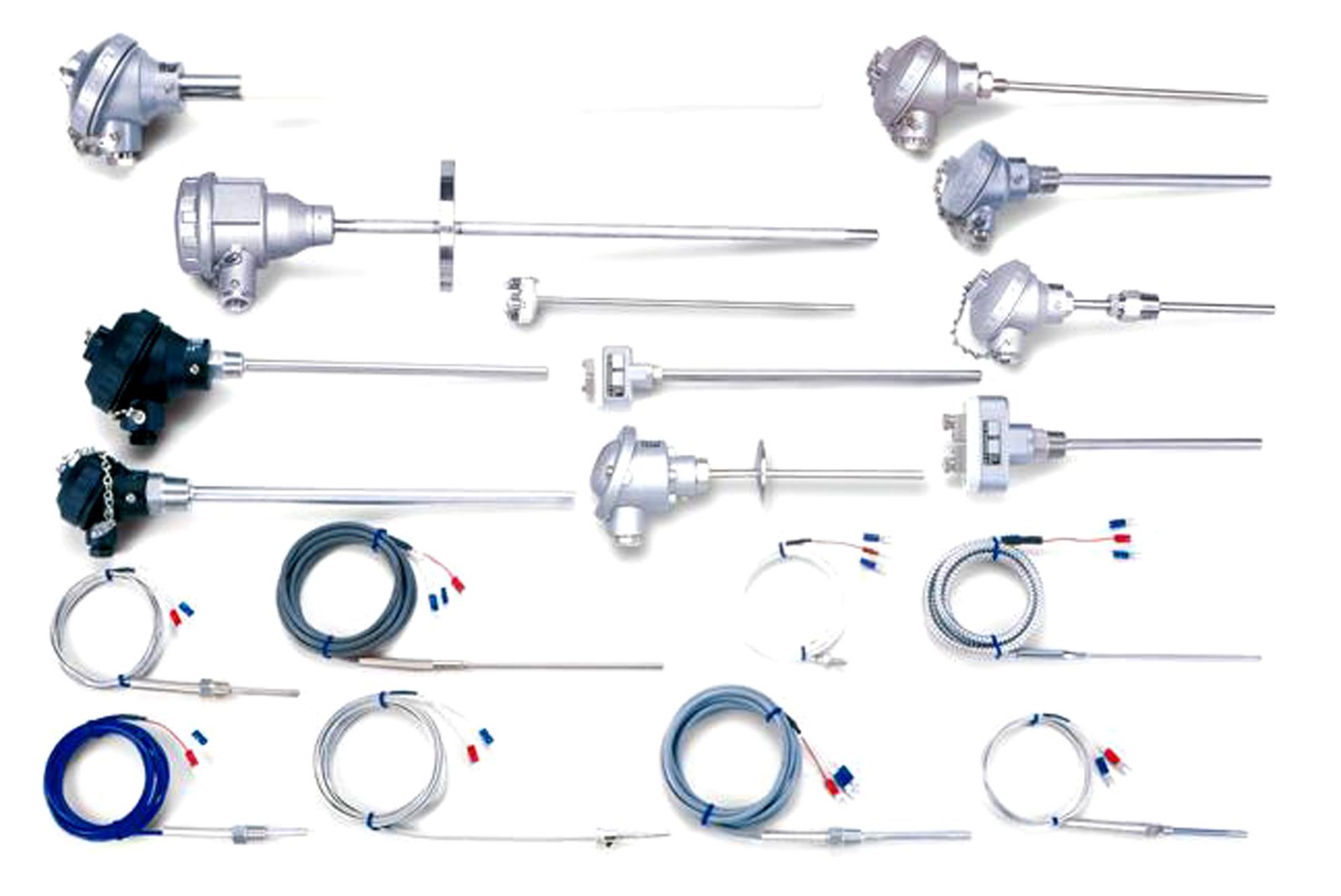

PT100 Temperature Sensors

Platinum Resistance Temperature Detectors for precise temperature measurement

Industrial PT100 temperature sensors for process control applications

PT100 Sensors Working Principle

Precision Measurement

How PT100 Sensors Work:

- In an RTD, resistance increases with temperature.

- A precision measurement circuit measures resistance and converts it to temperature using calibration standards like IEC 60751.

- PT100 is often used with 2-wire, 3-wire, or 4-wire connections for different accuracy requirements.

2-Wire Connection

- Configuration: Simplest connection

- Accuracy: Lower accuracy

- Lead Resistance: Not compensated

- Applications: Short distances, basic measurements

3-Wire Connection

- Configuration: Most common industrial choice

- Accuracy: Good accuracy

- Lead Resistance: Partially compensated

- Applications: Standard industrial measurements

4-Wire Connection

- Configuration: Most accurate connection

- Accuracy: Highest accuracy

- Lead Resistance: Fully compensated

- Applications: Laboratory, precision measurements

Key Specifications

| Feature | What it Means | Typical Values |

|---|---|---|

| Standard Resistance @ 0°C | Resistance at reference temperature | 100 Ω (for PT100) |

| Temperature Range | Operating temperature limits | -200°C to +600°C (varies by design) |

| Tolerance/Accuracy Class | Measurement accuracy per IEC standards | Class A / Class B per IEC 60751 |

| Material | Construction materials | Platinum sensing element, stainless steel sheath |

| Response Time | Time to reach 63.2% of final value | 0.5 to 10 seconds (depends on design) |

| Temperature Coefficient | Resistance change per degree | 0.385 Ω/°C (for platinum) |

Accuracy Classes (IEC 60751)

| Class | Tolerance (±°C) | Application |

|---|---|---|

| Class AA | 0.1°C + 0.0017×|t| | Laboratory standards |

| Class A | 0.15°C + 0.002×|t| | Precision industrial |

| Class B | 0.3°C + 0.005×|t| | General industrial |

| Class C | 0.6°C + 0.01×|t| | Basic measurements |

Resistance vs Temperature

- At 0°C: 100.00 Ω

- At 100°C: 138.51 Ω

- At 200°C: 175.86 Ω

- At 300°C: 212.05 Ω

- At 400°C: 247.09 Ω

- At 500°C: 280.98 Ω

PT100 Sensor Types

Wire-Wound Sensors

- Construction: Platinum wire wound on ceramic

- Accuracy: High stability

- Vibration: Good resistance

- Applications: Industrial processes

Thin Film Sensors

- Construction: Platinum film on ceramic substrate

- Cost: Economical

- Size: Compact design

- Applications: HVAC, Appliances

Industrial Probes

- Construction: Stainless steel sheath

- Protection: IP67, IP68 ratings

- Mounting: Threaded, flange, compression

- Applications: Process industries

Seal Kits

Maintenance seal kits for pneumatic cylinders and valves

Genuine seal kits for Festo and Janatics pneumatic components

Festo Seal Kits

Genuine Parts

Festo has genuine seal kits or compatible kits used for its pneumatic cylinders and valves. They're typically specific to the cylinder bore and design (e.g., DNC series, rodless types, compact cylinders).

Common Festo Seal Kits:

- Festo Seal Kit OL 1/2 - For standard cylinders

- Festo Seal Kit PVC O 1 - PVC cylinder seals

- Festo Seal Kit OK 3/8 - Medium size cylinders

- Festo Seal Kit O M5 / OK M5 - Metric thread seals

- 1/8″ Festo Type Complete Seal Kit - Small cylinder kits

Kit Contents:

- Piston seals (O-rings, U-cups)

- Rod seals and wipers

- Gaskets and backup rings

- Lubrication grease

- Installation instructions

Janatics Seal Kits

Indian Standard

Janatics is a major Indian pneumatic brand. Seal kits for Janatics cylinders are typically referenced by model series and bore diameter.

| Seal Kit Code | For Cylinder Bore | Series | Contents |

|---|---|---|---|

| SK 0002 / SK 0012 | Ø40 mm cylinder | A10/A11/A50 | Complete seal set for 40mm |

| SK 0003 / SK 0013 | Ø50 mm cylinder | A10/A11/A50 | Complete seal set for 50mm |

| SK 0004 / SK 0014 | Ø63 mm cylinder | A10/A11/A50 | Complete seal set for 63mm |

| SK 0005 | Ø80 mm cylinder | A10/A11/A50 | Complete seal set for 80mm |

| SK 0006 | Ø100 mm cylinder | A10/A11/A50 | Complete seal set for 100mm |

| SK 0007 / SK 0008 | Ø125/Ø160 mm | A10/A11/A50 | Large size kits |

| SK 0051 / SK 0053 / SK 0054 / SK 0055 | Various sizes | A23, A24, A27, A28 | Kits for other series cylinders |

Seal Materials & Types

Common Seal Materials

| Material | Temperature | Media | Applications |

|---|---|---|---|

| NBR (Nitrile) | -30°C to +100°C | Air, oil, water | Standard pneumatic |

| PU (Polyurethane) | -40°C to +80°C | Air, water | High wear resistance |

| Viton (FKM) | -20°C to +200°C | Chemicals, oil | High temperature |

| EPDM | -40°C to +150°C | Steam, hot water | Food, pharmaceutical |

Seal Types

O-Rings

U-Cups

Rod Seals

Piston Seals

Wipers

Backup Rings

Gaskets

Bearing Rings

Replacement Guidelines:

- Replace seals during preventive maintenance

- Use correct lubricant during installation

- Clean cylinder thoroughly before assembly

- Follow torque specifications

Solenoid Coils

Electromagnetic coils for solenoid valve actuation

Industrial solenoid coils for various voltage ratings

Solenoid Coil Specifications

UniversalElectrical Specifications:

- Wide voltage range: 12V DC, 24V AC/DC, 110V AC/DC, 220V AC

- Insulation class: Class F (155°C) or Class H (180°C)

- Coil protection: IP65 (dust-tight and water-resistant)

- Duty cycle: Continuous (100%)

Physical Specifications:

- Connection types: DIN connector or flying lead wires

- Operating temperature: ~0°C to 80°C

- Coil material: Copper winding

- Housing material: Plastic, Aluminum

Voltage Types & Applications

12V DC

- Mobile equipment

- Automotive applications

- Battery-powered systems

- Low voltage safety

24V DC

- PLC control systems

- Industrial automation

- Control panels

- Most common industrial

110V AC

- North American standard

- Commercial equipment

- Light industrial

- Export machinery

220V AC

- European/Asian standard

- Heavy industrial

- Direct line connection

- High power applications

Coil Types & Features

Connection Types

| Type | Description | Advantages |

|---|---|---|

| DIN Connector | Standardized plug connection | Quick disconnect, Protected |

| Flying Leads | Direct wire connection | Simple, Low cost |

| Terminal Box | Enclosed connection box | Weatherproof, Safe |

| Plug-in | Quick plug connection | Easy maintenance |

Protection Features

- Overload Protection: Built-in thermal protection

- LED Indicator: Power-on indication

- Manual Override: Manual operation button

- Surge Protection: Suppression diode/varistor

- Explosion Proof: ATEX certified options

Solenoid Coil Selection Guide

Selection Parameters:

- Voltage: Match control system voltage

- Connection: DIN or flying leads

- IP Rating: Environment protection needed

- Temperature: Ambient temperature range

- Valve Compatibility: Coil mounting dimensions

Common Mistakes to Avoid:

- Mixing AC and DC coils

- Using wrong voltage rating

- Ignoring IP rating requirements

- Not considering duty cycle

- Overlooking manual override need

Instrumentation & Maintenance Products Overview

| Product Category | Key Brands | Applications | Key Features | Typical Industries |

|---|---|---|---|---|

| PT100 Sensors | Various manufacturers | Temperature measurement | High accuracy, Platinum element | Process, HVAC, Manufacturing |

| Seal Kits | Festo, Janatics | Pneumatic maintenance | Genuine parts, Complete sets | Maintenance, Repair, Overhaul |

| Solenoid Coils | Various brands | Valve actuation | Multiple voltages, IP65 protection | All industrial sectors |

Technical Support & Contact

Complete Industrial Solutions

We provide comprehensive industrial products including instrumentation, pneumatic components, and maintenance parts for various industrial applications.

Instrumentation

- PT100 temperature sensors

- Pressure transmitters

- Temperature controllers

- Measurement instruments

Maintenance Parts

- Seal kits for cylinders/valves

- Solenoid coils

- Replacement parts

- Maintenance tools

Technical Services

- Product selection assistance

- Installation guidance

- Troubleshooting support

- Spare parts supply